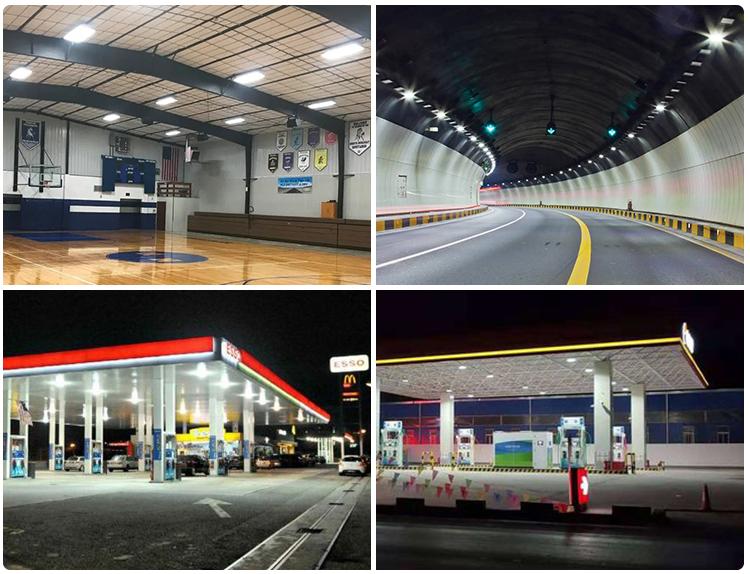

Tunnel lights are a vital component of transportation infrastructure, designed to provide consistent, glare-free illumination inside road tunnels, underpasses, mining shafts, and similar enclosed environments. Unlike general outdoor lighting, tunnel lighting must address specific challenges—such as low natural light, driver adaptation, high humidity, dust, and vehicular vibration. As a leading manufacturer of LED tunnel lights, we offer robust, high-efficiency lighting systems tailored to meet the demanding standards of tunnel environments. With advanced optics, anti-glare lenses, and rugged housings, our products ensure safe driving visibility, reduced maintenance, and optimal energy use across long tunnel spans. A tunnel light is a high-intensity, wide-beam lighting fixture installed in tunnels or enclosed transit passages to ensure safe and comfortable visibility. These lights are typically ceiling- or wall-mounted in rows to provide consistent luminance levels and help drivers smoothly adapt when entering or exiting a tunnel. Modern LED tunnel lights offer several advantages over traditional HPS or fluorescent tunnel lamps: Lower energy consumption Longer lifespan Better color rendering and visibility Instant ON/OFF with no warm-up Reduced maintenance cost Using top-tier COB or SMD LEDs, our tunnel lights deliver 130–160 lm/W for optimal brightness and efficiency. Rugged aluminum housings with tempered glass or PC lenses, built to resist dust, humidity, and water ingress. Precise light distribution with batwing or asymmetric optics, reducing glare and driver discomfort. Tested to IK08–IK10 impact standards, ideal for tunnels with constant vehicle movement and shock. Compatible with AC85–265V, and equipped with 6kV–10kV surge protection for safe operation in harsh conditions. Support for DALI, 0–10V, PWM, or timed dimming for energy-saving tunnel lighting control systems. Tunnel Lamp, Led Tunnel Light, Tunnel Led Light, Tunnel Flood Light, Outdoor Tunnel Light Jiangmen Synno Lighting Co., Ltd. , https://www.synnoled.com

The working frequency of an electronic tag is a fundamental characteristic of the RFID system, as it determines how the system operates. This frequency not only defines whether the system uses inductive or electromagnetic coupling but also influences factors such as read range, tag complexity, and overall system cost.

RFID tags operate at various frequencies, which are typically assigned within the ISM (Industrial, Scientific, and Medical) bands. Common operating frequencies include 125kHz, 133kHz, 13.56MHz, 27.12MHz, 433MHz, 902–928MHz, 2.45GHz, and 5.8GHz. Each frequency band offers distinct advantages and limitations, making them suitable for different applications.

Low-frequency (LF) tags operate between 30kHz and 300kHz, with common frequencies like 125kHz and 133kHz. These are usually passive tags that rely on inductive coupling from the reader’s coil. Their read range is generally less than one meter, and they are often used for animal identification, tool tracking, and vehicle anti-theft systems. LF tags are known for their low cost, energy efficiency, and ability to penetrate materials like water and organic tissue. However, they have limited data storage and are only suitable for short-range, low-speed applications.

High-frequency (HF) tags, operating around 13.56MHz, share similar inductive coupling mechanisms with LF tags but offer faster data transfer rates. They are commonly found in contactless smart cards, such as electronic IDs and access control systems. HF tags are also passive and have a read range of up to 1.5 meters. International standards like ISO 14443 and ISO 15693 govern their use.

Ultra-high frequency (UHF) and microwave tags operate at higher frequencies, such as 860–930MHz, 2.45GHz, and 5.8GHz. These tags can be active or passive and support longer read ranges—often exceeding 10 meters. UHF and microwave tags are ideal for logistics, inventory management, and vehicle tracking. Due to their extended range, they require multi-tag reading capabilities, which has become a key feature in modern RFID systems. Passive UHF tags are widely used in supply chain applications, while semi-passive and active tags are used where longer distances and more power are needed.

Microwave tags typically have smaller memory capacities, ranging from 64 bits to 2K bits, and are not designed for large data storage. Instead, they focus on efficient item identification. Standards such as ISO 18000-6 and ANSI NCITS256 define their specifications. These tags are used in applications like warehouse management, toll collection, and asset tracking.

In summary, the choice of RFID frequency depends on the specific application requirements, including read distance, data speed, cost, and environmental conditions. Understanding these factors helps in selecting the most appropriate RFID technology for a given use case.

Best LED Tunnel Light Manufacturer and Outdoor LED Lighting Fatory in China

What Is a Tunnel Light?

Types of Tunnel Lights

Type

Description

Applications

Fixed Tunnel Light

Non-adjustable, direct mount

Standard tunnels and underpasses

Adjustable Tunnel Light

Tiltable bracket or swivel mount

Sloped tunnels or specific beam direction

Linear Tunnel Light

Elongated for even lighting

Subway tunnels, corridors

Explosion-Proof Tunnel Light

Flameproof design

Mining tunnels, oil/gas sectors

Smart Dimmable Tunnel Light

Sensor or control-based brightness

Entrance, exit, or adaptive lighting systems

Key Features of Our LED Tunnel Lights

✅ 1. High Lumen Output

✅ 2. IP66 / IP67 Waterproof Rating

✅ 3. Anti-Glare & Optical Lens Design

✅ 4. Impact and Vibration Resistant

✅ 5. Wide Voltage & Surge Protection

✅ 6. Smart Lighting Ready

Classification of electronic labels

Â