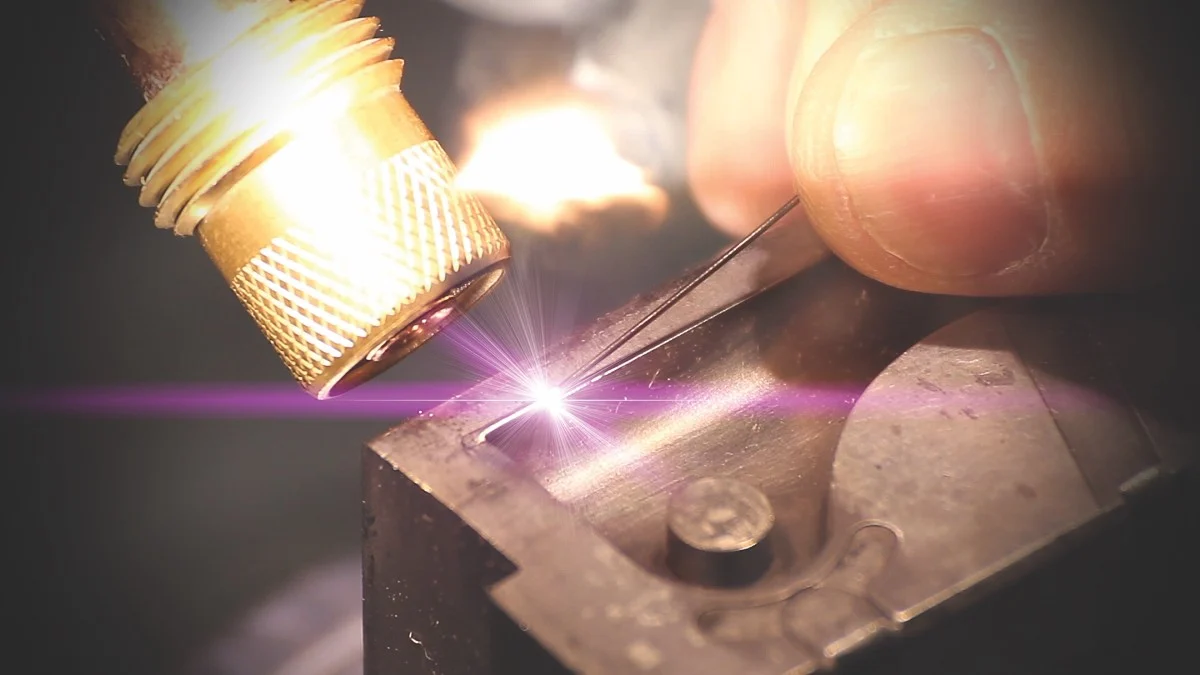

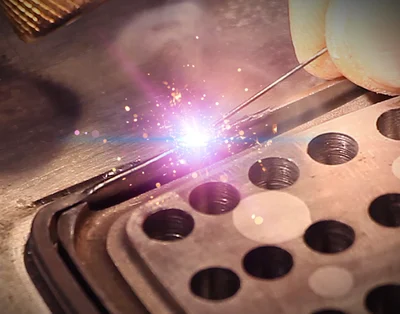

Quick Links Laser welding is an advanced welding technique that utilizes a highly focused, narrow laser beam to generate intense heat in very small areas. This intense heat melts the materials being joined together, allowing for precise bonding. The high intensity of the laser beam provides exceptional precision and control, making it possible to join even the smallest or most intricate parts with consistent results. As a result, laser welding is widely used in industries that demand precision, such as automotive, aerospace, and medical device manufacturing. Compared to traditional welding methods, laser welding offers several advantages. It provides extreme precision and accuracy, penetrates deeply into hard-to-reach areas, and is cost-effective relative to other processes. Additionally, because of its minimal heat input, it has negligible effects on nearby structures or components. Furthermore, this method can significantly reduce labor costs by eliminating most of the preparatory steps, such as grinding and preheating, required in traditional welding techniques like arc welding and spot welding. Mold repair involves addressing damage to molds used in industrial settings. This can include modifications and adjustments to the shape, size, or condition of a mold cavity. Mold repair can be complex and often requires a combination of methods, including grinding, machining, welding, and more. Sometimes, multiple approaches are needed to restore the mold to its original condition. Industrial molds are commonly made of metal, such as steel or aluminum, and are designed for injection molding to create various plastic parts. Poor maintenance and suboptimal design can cause damage and deformation after repeated use. Regular maintenance and inspection are essential, but sometimes an industrial mold may still require repair due to extreme temperatures or stress from overuse or improper part ejection from the tool cavity. When repairing a mold, several factors must be taken into account, such as the material integrity and dimensional accuracy of the parts being produced, as well as the specific conditions of the production environment. The primary goal is usually to restore the tool to its original specifications while maintaining the quality of the parts produced. This requires precision, accuracy, and, in many cases, careful heat management—making laser welding a perfect fit for these tasks. Laser welding is ideal for modifying and repairing molds, tools, and dies, whether due to damage, wear and tear, or changes in workpiece design. The process is quick, precise, and does not damage surrounding surfaces. As a result, tool and die shops using laser welding systems are often impressed by the broad range of applications and the ability to produce high-quality products faster with fewer materials while minimizing excessive heat effects. Consider Wicked Welding Inc., located in Dayton, OH, which was seeking a reliable laser welding solution to enhance the services offered to their industrial clients. According to their President, Pete Mourouzis, "Just six months after purchasing our manual laser welder, it accounted for about 30% of our sales. Transitioning from microscope GTA welding was smooth and rapid. Within just two days of receiving our LaserStar Laser Welding Workstation, we were operational and had already repaired our first mold. I am confident of a quick return on investment." Wicked Welding specializes in laser welding and takes pride in the quality of work they achieve using a laser welding system purchased from LaserStar. One of the key aspects that made manual laser welding suitable for tool and die or mold manufacturing and repair was the development of the "free-moving" concept. With this approach, the laser generates a stationary infrared light pulse targeted through the microscope's crosshair. The laser pulse can be adjusted in both size and intensity. Since the heat generated remains localized, operators can handle or fixture items manually, allowing for precise laser welding of small areas without harming their fingers or hands. This free-moving concept eliminates the need for costly fixturing devices and expands the range of assembly and repair applications. As a result, companies improve safety while enhancing their products and services, delivering consistently high-quality results quickly. And, as demonstrated by Wicked Welding, you can achieve excellent return on investment and see benefits rapidly. Mold repair demands precision, accuracy, and meticulous attention to detail. It requires an understanding of the laser welding process and how to leverage the tools effectively to achieve desired outcomes. It also calls for outstanding customer service and support, which is a cornerstone of LaserStar’s business philosophy. We understand our machines thoroughly, and for many clients, the sale marks the beginning of a long-term partnership rather than the end. We provide ongoing support and training to ensure success. In addition to this support, LaserStar micro welding laser systems are ideal for a wide range of large plastic injection mold, tool, and die maintenance and repair applications. Some notable benefits include: LaserStar micro welding laser systems deliver high-quality results, reduce the amount of handwork required before polishing, and virtually eliminate sink lines. Whether you're looking to enhance your current repair work or introduce laser welding to your services, we would love to discuss how we can help. Get in touch with the team at LaserStar and let’s grow—and weld—together.   Steel Galvanzed Cable Rack,Customized Cable Rack Foshan Shengbang Steel Structure Co.,Ltd , https://www.sbsstructure.com Today’s small precision welding shops that specialize in plastic injection mold, dies, and tooling repair have access to a wide range of cutting-edge technologies. These advancements enable them to offer the highest level of quality, craftsmanship, and service to their clients. One of the fastest-growing technologies in this field is the adoption of manual micro-welding laser systems as an alternative to traditional microscope GTA welding. This shift is helping businesses stay competitive and meet the ever-increasing demands of their customers.

Today’s small precision welding shops that specialize in plastic injection mold, dies, and tooling repair have access to a wide range of cutting-edge technologies. These advancements enable them to offer the highest level of quality, craftsmanship, and service to their clients. One of the fastest-growing technologies in this field is the adoption of manual micro-welding laser systems as an alternative to traditional microscope GTA welding. This shift is helping businesses stay competitive and meet the ever-increasing demands of their customers.

What is Laser Welding?

What is Mold Repair?

What is Mold Repair?Who is Choosing Laser Welding for Mold Repair: A Brief Case Study

Why Choose LaserStar Welders for Mold Repair

Why Choose LaserStar Welders for Mold Repair