Molecular formula: C6H11O7Na

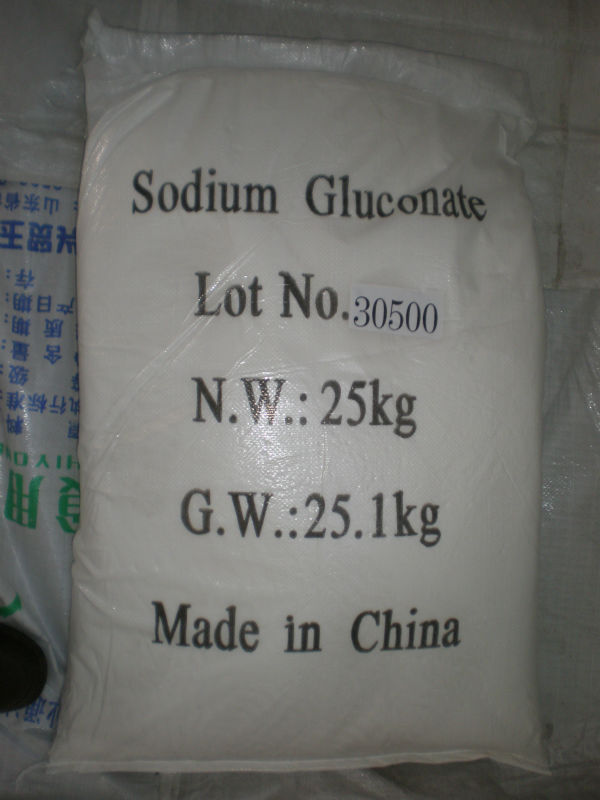

Packing: 25kg in plastic film bag lined plastic woven bag, or following your demand

Sodium Gluconate,Nano Silica,Concrete Retarders Sodium Gluconate,Construction Chemical 99% Sodium Gluconate Shandong Tiancheng Chemical Co., Ltd. , https://www.akdchemical.nl

On the first day of the Dragon Boat Festival holiday, nearly 700 robotics people gave up their vacations and rushed to Wuqing, Tianjin from all parts of the country. A meeting on robots was held here on the same day.

Many companies on the stage took turns to make their own products. Unexpected listeners have repeatedly repeated a question in the questioning field. “Is the speed reducer your own? Servo motor?†In the subsequent reply, the melodious tone just became a bit low and even inferior.

This is an awkward topic.

It is true that in the manufacturing sector, robots have become a hot concept. The disappearance of the demographic dividend, the increase in labor costs, and the transformation of the manufacturing industry have become the main arguments for promoting the future of the robot industry. Whether it is in the industry or outside the industry, whether it is machine tools or mice in the past, they all threatened to enter the robot market and share a piece of cake.

This kind of scene seems to be no stranger. Experience tells us that in the face of a generally optimistic sunrise industry, we never lack the enthusiasm of “big steelâ€, and all this is familiar.

Crazy layout

In another small conference room at the venue, Tianjin local media reporters let the Chinese Academy of Engineering academician Cai Hejun talk about the advantages of developing robots in Tianjin in a near-forced tone. Cai Hezhen faced the microphone and could only talk from Tianjin with a good foundation. On the same day, Cai Hejun and another academician Zhang Wei became consultants for the Tianjin Robotics Industry Technology Innovation Strategic Alliance.

Cai Hejun told reporters of China's economy and informatization that China, as a manufacturing power, has been lagging behind in robot applications, and the average occupancy rate of robots is even lower than that of North Korea. It is clear that China is the fastest growing regional market for robots in the world, and the number of newly installed industrial robots has doubled in the past five years. China's robot installations will double again in the next three years, and its demand is huge.

Such a big cake not only attracted the attention of the industry and the capital world, but also allowed local governments to discover a new opportunity to promote economic development.

The automobile industry park in Wuqing District, where the conference was held, planned to build the “Robot Industry, Industry, Education and Research Strategic Alliance Development Baseâ€. Tang Wanqiang, the person in charge, said that the park has introduced Dingqi Spindle, Chenxing Automation, Nainbo Technology, Tianruibo Technology and other national 863 robot science and technology achievements transformation projects. "The robot production R&D area has planned an area of ​​240,000 square meters. It will actively build a complete industrial chain integrating R&D, design, manufacturing and testing. It is expected to introduce 100 related companies within 5 years."

In the previous "Twelfth Five-Year Plan for the Development of Electronic Information Industry in Tianjin", Tianjin developed and developed industrial robots, police robots, safety robots, mining robots, underwater robots, and medical minimally invasive robots. . By 2015, it will have an annual production capacity of 5,000 kinds of robots, and the industrial scale will reach 20 billion yuan.

Not only Tianjin, Shenyang Fushun New City claims to build the country's largest robot industry base, with an estimated annual output value of 50 billion yuan; Shandong Qingdao New District is planning 1000 acres of land, to build the largest robot industry base in the north. In March 2013, Chongqing also passed the “Report on Accelerating the Development of the Robot Industry†of the Chongqing Economic and Information Technology Commission, and began planning to build a robot industrial park covering an area of ​​2 square kilometers in the Liangjiang New District. The local target is: by 2015, more than 30 enterprises will be formed, and 40,000 industrial robots and key components will be formed, with an annual production capacity of 20 billion yuan. By 2020, more than 200 enterprises will be formed and 100,000 will be formed. The annual production capacity of Taiwan industrial robots, 1 million service robots and 1000 special robots has reached an annual output value of 50 billion yuan.

In addition, Shanghai, Shenyang, Harbin, Changzhou, Tangshan, Xuzhou proposed dozens of cities planning and building robot industry parks, so that a robot industry website had to launch a selection. These industrial parks cover a larger area than one, and the planned production capacity is higher than one.

In the self-description of many robot industry parks, they all mentioned a paragraph: "According to IRF, China will become the world's largest industrial robot market in 2014, with sales of more than 35,000 units, up 60% from 2011. By 2015, global industrial robot sales will reach 200,000 units, and the global robot industry will reach 50 billion US dollars."

The United States has called for "returning to manufacturing," and hopes to revitalize US manufacturing through the development of artificial intelligence, robotics, and digital manufacturing technologies. The European Commission has proposed the concept of "new industrial revolution," emphasizing technological innovation and structural reform. Advancing new production methods include emerging industries such as robots and digital technologies; Japan and South Korea have also listed robots as future strategic emerging technologies and formulated detailed strategic development plans, which have become powerful theoretical support for the development of robots.

Luo Jun, executive chairman of the International Robotics and Intelligent Equipment Industry Alliance, said that although it is a good thing to attach great importance to the robotics and smart industries, not every place has the conditions for building robots and intelligent equipment industrial parks. It includes three aspects: First, it depends on whether it has a good industrial base, including scientific research resources, industrial resources, and talent base. Second, whether this place has a very large market radiation capacity, and through the introduction of technology, the construction base will form upstream and downstream. Industry agglomeration; the third is to see whether the local area has a very obvious material basis, and there are cost advantages when there are material advantages.

"If you don't have these three comparative advantages, or these three advantages are not very obvious, it is recommended not to blindly intervene." Luo Jun said.

Assembly factory?

Along with the rapid growth of China's economy and the demand of industries such as automobiles, China's demand for industrial robots has increased sharply. So far, among the top four robot manufacturers in the world, there is not even one Chinese company.

Another phenomenon is that Germany's KUKA, Japan's FANUC, Switzerland's ABB and Japan's Yaskawa have all entered the Chinese market. The robots and supporting companies in Italy, the United States and South Korea have also deployed in major parts of China. The price of foreign famous brand industrial robots has been declining year by year, which restricts the formation of China's industrial robot industry and realizes the development of scale.

These foreign robot brands have already occupied 90% of the domestic market, and so many domestic companies account for less than 10% of the market.

A few years later, we estimate that we will repeat a sentence that has become a cliché. "China is a big robot country, but it is not a robot powerhouse," said Ma Nan, deputy manager of the China Investment Consulting Industry Consulting Department.

This is not an alarmist. The development of China's industrial robots began with the scientific and technological research and implementation of the "863" plan. After the "seventh five-year" research and application engineering development supported by the "eighth five", "nine-five" and national "863" programs, the theoretical research and prototype were experienced. Four stages of research and development, demonstration application and initial industrialization.

Although China's industrial robot industry has developed rapidly, there is still a big gap in overall technology compared with foreign advanced levels, which is only equivalent to the level of foreign countries in the mid-1990s.

At present, the production scale of industrial robots is still small, most of them are single-piece and small-batch production. The key supporting unit components and devices are always in the state of import, and an imported reducer accounts for about 35% of the total cost of the robot. Subject to the technological monopoly of multinational corporations, it is difficult to “self-determine†and become the biggest problem restricting the development of China's robot industry.

"Foreign robots have strong comprehensive capabilities, such as key parts of materials, assembly processes, software algorithms, etc." Ma Nan said that some companies have tried to enter this field, but the results are not satisfactory. For example, the harmonic reducer of the component which is very important in the robot, the life made by the domestic material can only be one to two years, and the wear is very serious after one year, and the material of the harmonic reducer directly affects the speed and precision of the robot. The core algorithm of the robot, the domestic robot is not leading in the trajectory smoothing algorithm, so the robots such as grinding and welding are mostly foreign brands.

"In robot applications, many of the related control components such as sensors currently used with robots mostly use foreign brands. These brands are relatively stable in quality and have a long service life, and are also more practical for complex field environments. From these sensors and elements From the perspective of devices, there are gaps in domestic manufacturers."

In this regard, Zhao Jie, director of the Institute of Robotics at Harbin Institute of Technology, believes that the reason why the key technologies are subject to people is that although there are nearly 100 colleges and universities and enterprises in China that are engaged in the research and production of industrial robots, the research is too independent and closed. R&D is scattered, failure to form synergy, repeated research on the same technology, wasting a lot of research and development expenses and research and development time; most domestic enterprises are keen on large and comprehensive, and some enterprises with better research and development basis of key components of robots have turned into robots. Production, failed to form an orderly and detailed industrial chain of industrial robot development, production, manufacturing, sales, integration, and service.

Excessive worry

In a factory in the northeastern region that has just entered the robotics industry, the industrial robot body that has just been painted white paint is neatly arranged in a white flower, far away, like a flock. The person in charge of the company said to reporters with confidence, you see how spectacular this is.

On a "China Machinery Community" website with hundreds of thousands of members, there is also a debate about robots. Netizen dance Feiyang complained: "According to the current target of robot production capacity announced in the local planning, it has basically equaled the global total demand scale in 2015. Now what companies want to be robots, as long as they are connected with robots, the stock price will rise. Even the coal is used to engage in robotics."

As a well-known expert in the field of robotics, Zhao Jie is also worried that under the situation that the demand for industrial robots in China is growing rapidly, a large number of enterprises are optimistic about the industrial robot market, which has caused vicious competition of domestic industrial robots, which has reduced the profits of domestic industrial robots. No profit is profitable, and ultimately restricts the industrialization process of domestic robots.

"At present, the production capacity of more than ten major international industrial robots has met the demand for industrial robots in the international market, and it also has the ability to expand production." Zhao Jie judged.

Academician Cai Hejun hopes that after several years of practice, the big waves will be realized, and those enterprises with technical and economic strength will be able to settle down, making China's industrial robots enter the track of benign development.

Although some believe that almost all emerging industries will experience the initial era of barbaric growth, repeated construction and swarming is difficult to avoid.

However, after experiencing the roller coaster development of one sunrise industry, can we expect that the robot industry will not take the old road of photovoltaics and wind power and gain healthy growth.

Today, the robot industry is standing at the starting point of development.

Molecular weight: 218.14

Properties: white crystalline granule or powder, easy to dissolve in the water

Standard:

Quality standard

Item standard

Industry grade: food grade

Identification in: accordance with standard

Assay: ≥98.0%, 98.0 - 102.0%

Loss on dry: ≤0.50%; ≤0.30%

Reduzate: ≤0.70%; ≤0.50%

pH: 6.2 - 7.8; 6.2 -7.8

Sulfate: ≤0.05%; ≤0.05%

Chloride: ≤0.07; ≤0.07

Pb: ≤2μg/g; ≤1μg/g

Arsenic salt: ≤2μg/g; ≤2μg/g

Heavy metals: ≤10μg/g; ≤10μg/g

Appearance of solution (1.0g, 10ml water): colorless, almost clear

Usage:

1, In the medicine field, it can keep the balance of acid and alkali in the human body, and recover the normal operation of nerve. It can be used in the prevention and cure of syndrome for low sodium. In this purpose, it also can be used as Food Additives

2, It can be used as water quality stabilizer because it has excellent inhibiting capacity to scale

3, Used as surface cleaning agent of metal

4, Used as cleaning agent of glass bottle

5, It also can be used as water reducing agent and retarder in the building industry

Chinese-style robot industry welcomes the leap into the crazy layout

Abstract There is no doubt that robots are a sunrise industry with great potential. On the first day of the Dragon Boat Festival holiday, nearly 700 robotics people gave up their vacations and rushed to Wuqing, Tianjin from all parts of the country. A meeting on robots was held here on the same day. Many on the stage...

There is no doubt that robots are a sunrise industry with great potential.

Packaging & Shipping