Capsule Elevator,Scenic Passenger Lift Elevator,Luxurious Capsule Elevator,Glass Capsule Elevator APSL ELEVATOR TECHNOLOGY(SUZHOU) CO.,LTD. , https://www.fujiapsl.com

Both PEEK and PTFE screws demonstrate remarkable high-temperature stability, withstanding up to 500°F, surpassing the performance of PVDF and nylon. For applications requiring maximum strength at extreme temperatures, reaching up to 572°F, Vespel stands out as the superior option.

PVDF materials meet stringent regulatory standards, including approval by the FDA, USDA, NSF, 3A Dairy, and USP Class VI. These screws also resist ultraviolet degradation and withstand standard sterilization processes, making them ideal for industries such as pharmaceuticals, food processing, and semiconductors.

PTFE fasteners excel in corrosion resistance, providing protection against most organic compounds, acids, and bases—even hydrochloric acid. With a maximum operating temperature of 500°F, they are perfect for high-temperature corrosion-resistant applications but are relatively weak. PVDF screws offer a high degree of chemical resistance and greater strength than PTFE, though they are typically used in environments below 300°F. PEEK screws exhibit less corrosion resistance compared to PVDF but still rank highly among polymer fasteners in terms of durability.

In terms of sheer strength, PEEK screws lead the pack. PEEK outperforms PTFE, PFA, PVDF, and even Vespel in many cases. While natural PEEK is already robust, fiber-reinforced PEEK variants, such as PEEK Extreme and glass-filled PEEK fasteners, can rival the strength of certain steel fasteners.

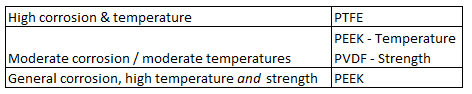

For applications demanding multiple capabilities, here are our top recommendations:

Which Polymer Is Right for You?

PEEK, PVDF, and PTFE all provide lightweight solutions with excellent electrical and thermal insulation properties, along with impressive corrosion resistance. However, when it comes to strength, temperature tolerance, purity, and corrosion resistance, each material excels in its own niche. This newsletter highlights which material is best suited for various conditions.

TEMPERATURE

ULTRA PURITY

CORROSION RESISTANCE

STRENGTH

TOP PICKS

Each of these materials brings unique advantages to the table, ensuring optimal performance across diverse industrial applications. Whether you're designing for extreme temperatures, ultra-purity requirements, or enhanced corrosion resistance, selecting the right material is key to success.