The 19th Beijing Essen Welding & Cutting Fair Smart Drawer Cabinet,Classic Chest Cabinet Of Drawers,Chest Of Drawers Vertical Style Jiangsu Xicang Intelligent Technology Co., Ltd. , https://www.xciwarehousing.com

Selection and Thinking of Welding Materials for Bridge Steel Structures

Main Products and Common Welding Consumables

Our company is a leading comprehensive enterprise in the domestic railway turnout and bridge manufacturing industry. We have always been at the forefront of bridge steel structure manufacturing, enjoying a strong reputation both domestically and internationally. We are often referred to as the "cradle of China's steel bridges." Currently, we are involved in the manufacturing of major projects such as the Hong Kong-Zhuhai-Macao Bridge, the Verrazano Strait Bridge in New York, and the Yalu River Bridge.

The primary grades of structural steel used in domestic bridges are Q370 and Q345, with some applications of Q390 and Q420. These materials comply with national standards such as "Low Alloy High Strength Structural Steel" (GB/T 1591-2008) and "Structural Steel for Bridges" (GB/T 714-2008). Higher strength grades have not yet been widely applied in bridge engineering. In the manufacturing process, submerged arc welding and gas-shielded welding are commonly used, with a small amount of electrode arc welding. A table of commonly used welding materials is provided below for reference.

Depending on the structural form of the steel bridge, the proportion of welding materials used varies: 1) For highway steel box girder bridges, gas-shielded welding accounts for about 85%, while submerged arc welding makes up around 15%, and electrode arc welding is approximately 2%. 2) For truss bridges, submerged arc welding is used in large quantities, accounting for about 58%, gas-shielded welding around 40%, and electrode arc welding about 2%.

Challenges in Selecting Welding Materials During Production

(1) The selection of high-quality welding materials is limited. As the strength and toughness requirements for bridge steels continue to rise, there is an increasing demand for high-strength, high-toughness, and low-hydrogen welding materials. For example, the Q420qE steel plates used in the Nanjing Dashengguan Yangtze River Bridge require welded joints with impact absorption energy of at least 48J at -40°C. For Q345qE and Q370qE steel plates, the required impact absorption energy at -40°C is at least 47J. However, current welding material standards typically require only 27J or 34J, which is lower than the mechanical properties needed for actual products. Additionally, the weld metal’s strength should not exceed that of the base metal, meaning there is a limit to how much higher the weld can be in strength. For instance, the butt welds must not exceed the base metal by more than 100 MPa, and fillet welds must not exceed it by more than 120 MPa.

With the development of steel bridges toward greater heights, heavier loads, full welding, and larger sections, the crack resistance of welding consumables is becoming increasingly important. There is also a growing need for lower diffusible hydrogen content. For example, the Hong Kong-Zhuhai-Macao Bridge requires ultra-low hydrogen welding materials with a diffusible hydrogen content of ≤5mL/100g, which poses high demands on flux-cored wire production. Due to the high R&D costs, low usage, and low profit margins, the development of high-quality welding materials in China has not kept pace with the advancement of high-performance steel sheets, resulting in a limited number of high-quality options available.

(2) The qualification certificates for welding materials used in foreign projects are incomplete. In recent years, our company has successfully manufactured steel bridges and hydraulic structures in countries like the United States, Germany, and Canada. However, differences in welding quality management systems, technical standards, and welder qualifications mean that welding consumables must meet different certification requirements. For example, EU steel structures require CE certification for welding consumables, while American structures require ABS certification. Canadian structures may require CWB certification. In contrast, Chinese welding consumables typically have ABS or classification society certifications, but fewer have CE or CWB certifications. Some materials are not available in China and must be imported.

Expectations and Suggestions for the Future Development of Welding Consumables

(1) Reduce dust, wastewater, noise, and environmental pollution during the production of welding materials.

(2) Improve the processability of welding consumables, reduce smoke generated during welding, and minimize environmental impact and health risks for welders.

(3) Enhance the formulation of welding materials, improve deposition efficiency, and develop high-efficiency, energy-saving welding consumables.

(4) With the increasing use of welding robots and special welding machines in steel bridge manufacturing, green welding workshops are emerging. This trend will lead to a significant increase in the use of gas-shielded welding consumables for robotic and specialized welding equipment in the steel bridge industry.

More exciting content Welcome to Metalworking Online》》》Essen Special Report

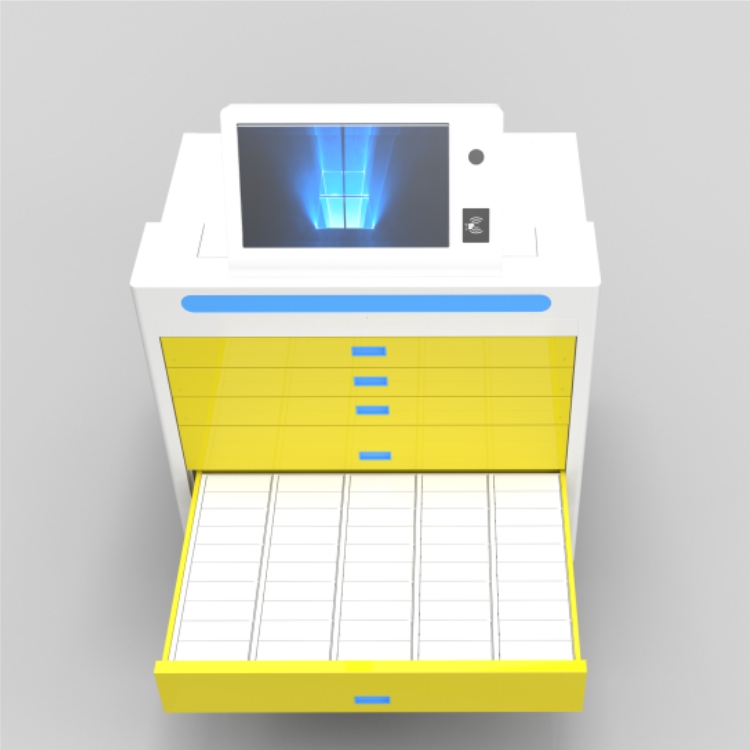

Jiangsu XC Intelligent Technology Co., Ltd. is a pioneer in the field of industrial segmentation, a comprehensive solution provider that integrates software and hardware development, industrial digital intelligence, and industrial cost reduction and efficiency improvement..Our company's main business includes intelligent tool cabinets, intelligent tool handle management cabinets, intelligent protective equipment management cabinets, intelligent tool management cabinets, intelligent standard parts and consumables management cabinets, intelligent power public goods management cabinets, and so on; Integrators and manufacturers of solutions for the MRO category.External dimensions: 1210mm long; 880mm wide; 1640mm high

Grid size: Small grid size: 75 * 40 * 60mm, 240 pieces

Large grid: 150 * 40 * 130mm, 150 pieces

Screen size: 21.5-inch capacitive touch screen

Product color: yellow white

Recognition methods: facial recognition, card swiping, and inputting work ID

Applicable system: card swiping, facial recognition

Power supply: AC220V